G.T. Heater, Control & Sensor

a division of 2370632 Ontario Inc.

7170 16th Sideroad

Schomberg , Ontario

Canada L0G 1T0

office: (416) 741-7749

Email:

gtheater@gtheater.net

Heater search:

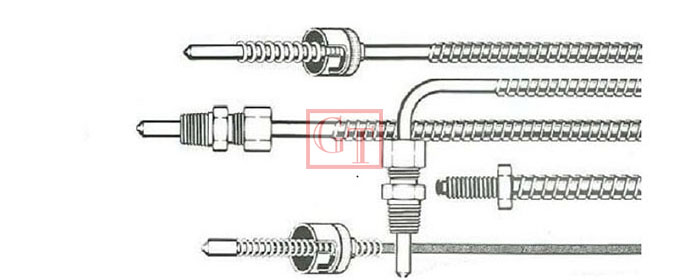

Band Heaters / Mineral Insulated

Mineral insulated band heaters are rugged and heavy duty heaters made for applications that require high temperatures (up to 1400ºF) and high watt densities (up to 100 W/in²). These heaters are ideal for increasing output especially in injection molding and to meet the heating requirements to process newly engineered high tech resins.

The nickel chrome resistive material inside a mineral insulated heater is embedded in Aluminum Oxide insulating medium which provides excellent heat transfer and dielectric strength. A stainless steel outside casing gives external protection.

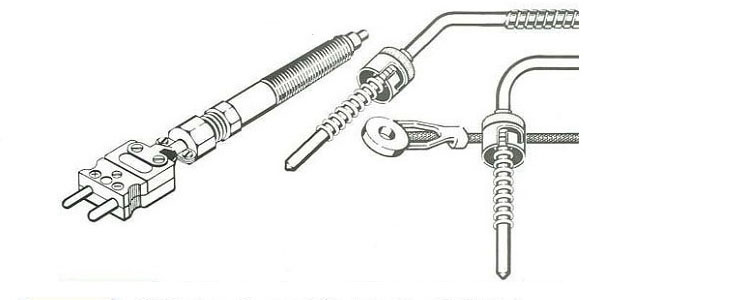

Mineral insulated band heaters are made with various clamping mechanisms, electrical termination styles, thermocouples and can be manufactured with holes and cut-outs.

Physical and electrical ratings and limitations

Max ID for one piece construction: 14in

Mineral insulated band heaters are rugged and heavy duty heaters made for applications that require high temperatures (up to 1400ºF) and high watt densities (up to 100 W/in²). These heaters are ideal for increasing output especially in injection molding and to meet the heating requirements to process newly engineered high tech resins.

The nickel chrome resistive material inside a mineral insulated heater is embedded in Aluminum Oxide insulating medium which provides excellent heat transfer and dielectric strength. A stainless steel outside casing gives external protection.

Mineral insulated band heaters are made with various clamping mechanisms, electrical termination styles, thermocouples and can be manufactured with holes and cut-outs.

Physical and electrical ratings and limitations

Max ID for one piece construction: 14inMax ID for two piece construction: 26in

Max width: 6in

Gap: 1/4in to 3/4in depending on width

Max width for heaters less than 3": Twice the diameter

Max voltage: 480V

Max amps for leads: 10 Amps

Max amps for screw terminals

(10-32 UNF): 22 Amps