G.T. Heater, Control & Sensor

a division of 2370632 Ontario Inc.

7170 16th Sideroad

Schomberg , Ontario

Canada L0G 1T0

office: (416) 741-7749

Email:

gtheater@gtheater.net

Heater search:

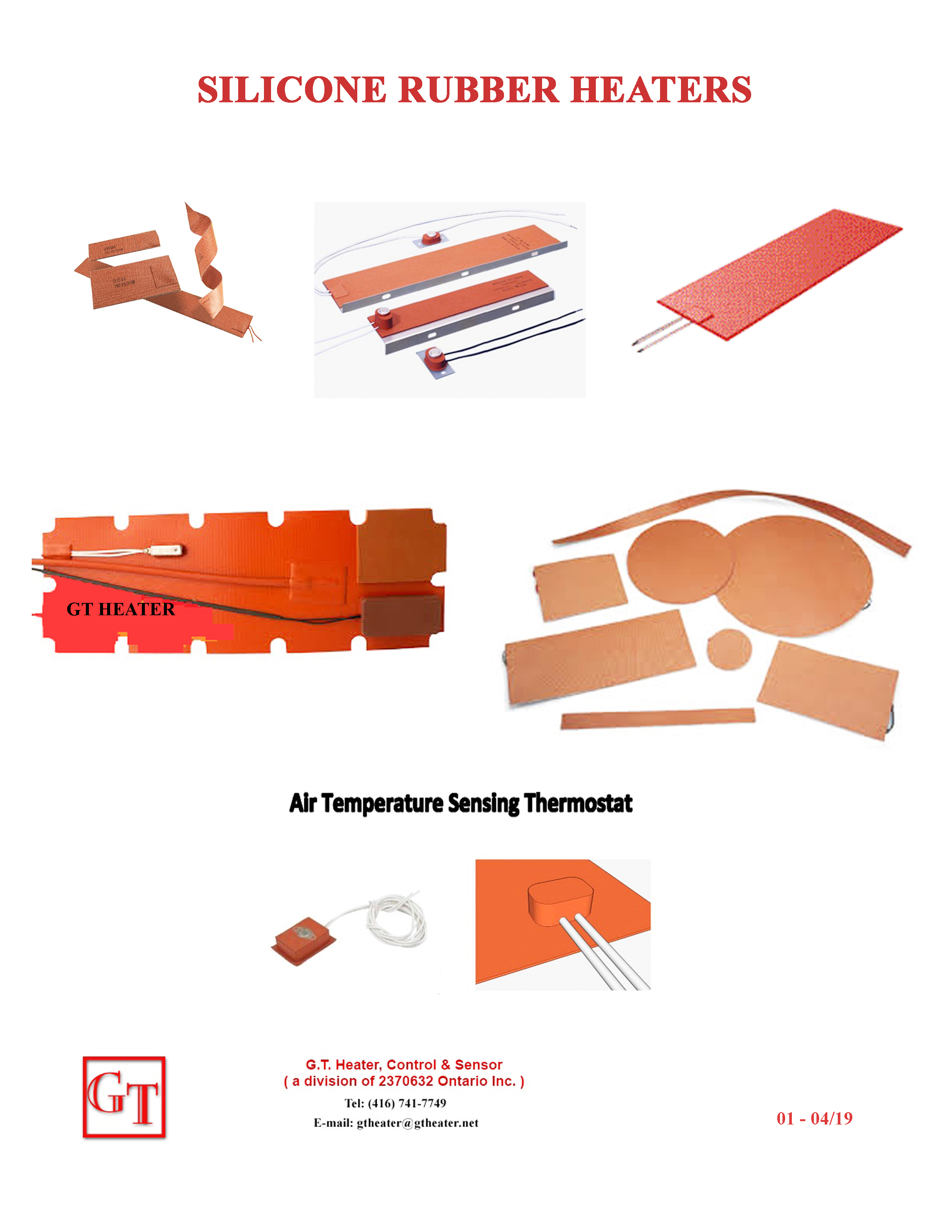

Silicone Rubber Heaters

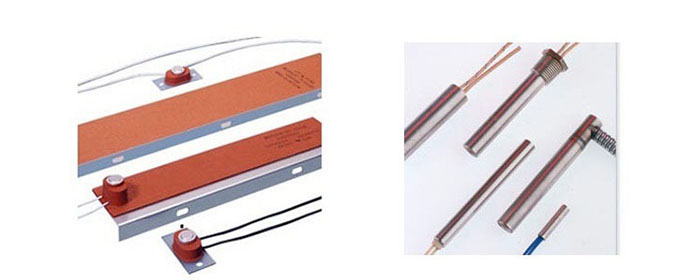

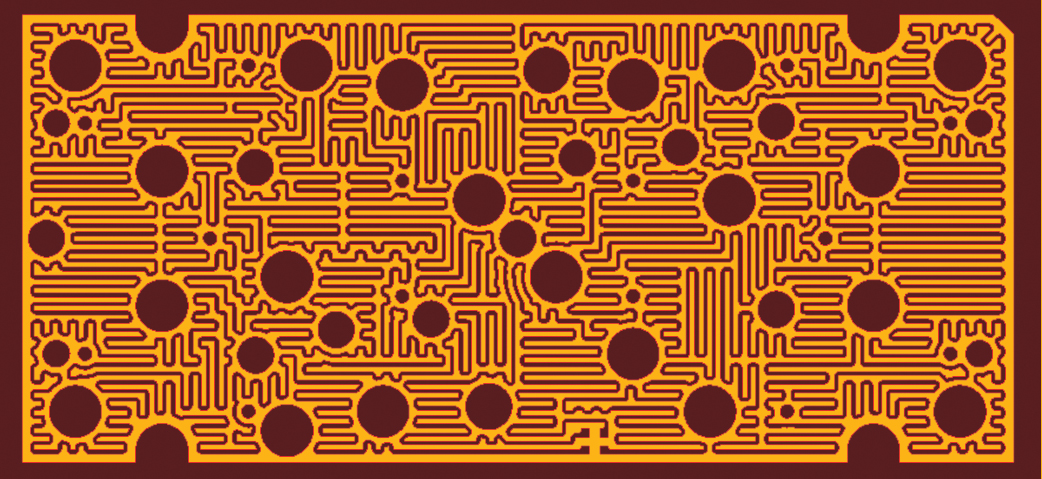

Silicone rubber heaters are flexible and lightweight heaters that  can operate up to 450°F. Because of their thin construction, the uniform heating pattern of its heating circuit and the closeness of this circuit to the surface of an application, the heat transfer from a silicone rubber heater is rapid and uniform. Despite being thin and flexible, silicone rubber heaters are rugged and maintain dimensional stability, due to the fiberglass grid that reinforces the silicone sheets that encapsulate the heating elements of these heaters. Silicone rubber heaters are moisture and chemical resistant and can adhere to flat or curved surfaces and can be factory vulcanized to metallic surfaces. These heaters can accommodate holes and cut-outs; they can be built with thermostats, thermocouples, RTDs or thermal fuses. Silicone rubber heaters can have different types of fasteners, and can be bonded to a surface by pressure sensitive adhesive (PSA) or room temperature vulcanizing paste (RTV).

can operate up to 450°F. Because of their thin construction, the uniform heating pattern of its heating circuit and the closeness of this circuit to the surface of an application, the heat transfer from a silicone rubber heater is rapid and uniform. Despite being thin and flexible, silicone rubber heaters are rugged and maintain dimensional stability, due to the fiberglass grid that reinforces the silicone sheets that encapsulate the heating elements of these heaters. Silicone rubber heaters are moisture and chemical resistant and can adhere to flat or curved surfaces and can be factory vulcanized to metallic surfaces. These heaters can accommodate holes and cut-outs; they can be built with thermostats, thermocouples, RTDs or thermal fuses. Silicone rubber heaters can have different types of fasteners, and can be bonded to a surface by pressure sensitive adhesive (PSA) or room temperature vulcanizing paste (RTV).

Industrial Applications

Industrial Applications

*Depending on temperature and application.

Silicone rubber heaters have two types of heating circuits; the wire-wound style and the etched-foil style. Each style has its unique characteristics and should be selected accordingly. Wire-wound circuits are formed by creating a specific pattern out of resistance wire that is spiraled around a fiberglass core. The etched foil circuit is a flat circuit that is formed by chemically etching a resistive circuit out of nickel alloy resistance foil.

- Photo processing equipment

- Freeze protection

- Computere equipment

- Medical equipment

- Condensation prevention for instruments and equipment

- Curing of plastic laminates

- Semiconductor processing equipment

| Silicone Rubber Heaters | Wire wound circuit | Etched foil circuit |

| Max size | 38” x 98” | 24” x 30” |

| Thickness | 0.060” | 0.030” |

| Max temp | 450°F | 450°F |

| Max voltage | 600 VAC | 480 VAC |

| Watt density | Up to 10 W/in2 * | Up to 30 W/in2 * |