G.T. Heater, Control & Sensor

a division of 2370632 Ontario Inc.

7170 16th Sideroad

Schomberg , Ontario

Canada L0G 1T0

office: (416) 741-7749

Email:

gtheater@gtheater.net

Heater search:

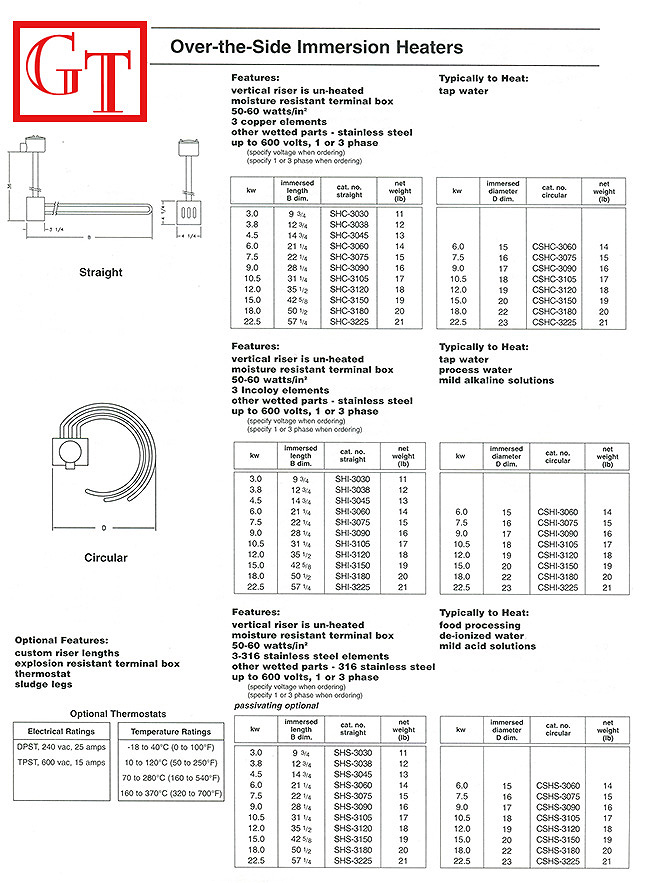

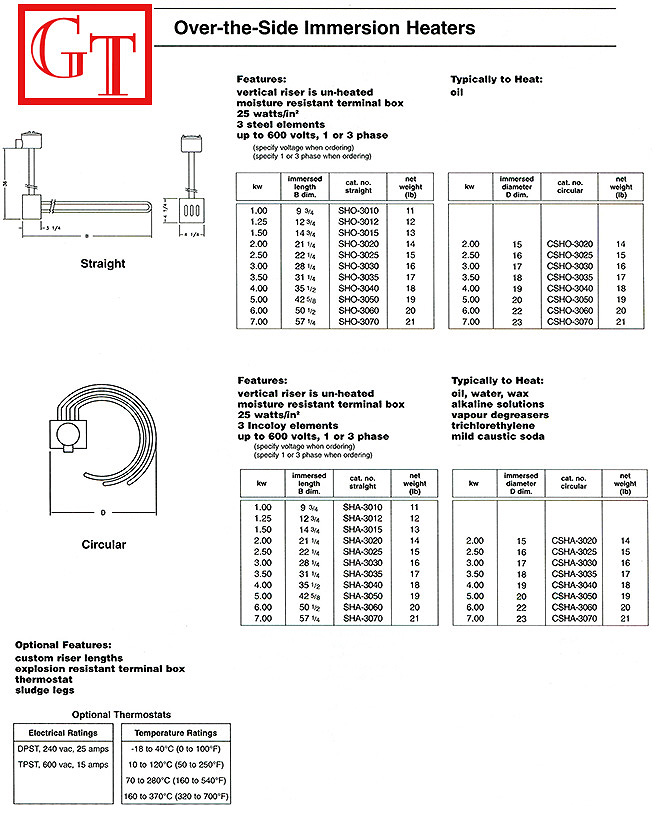

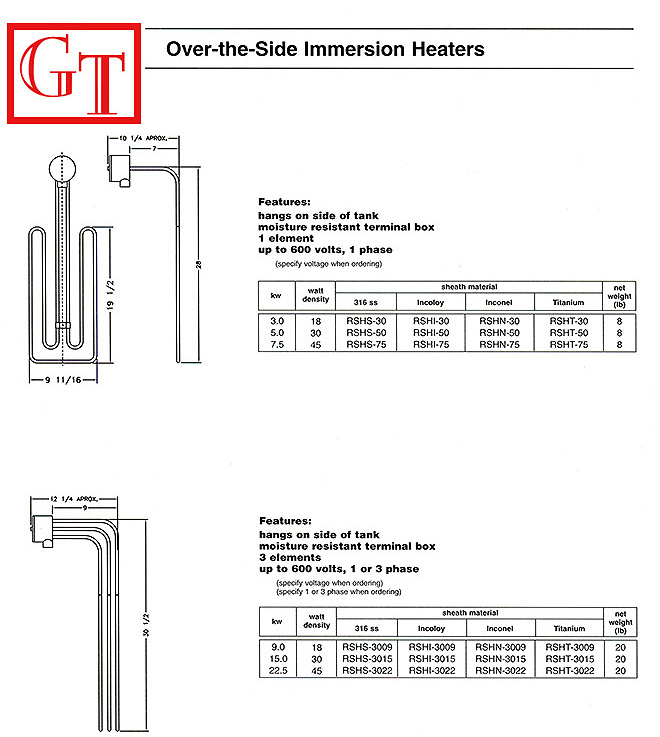

Over-the-Side Immersion Heaters

Over-the-side immersion heaters are for applications where installing a heater through the side wall of a vessel is not convenient. These immersion heaters are easy to install and can be moved from one tank to another without the need to drain the tank.

Over-the-side immersion heaters are ideal for applications where scale or sludge build-up on the heater sheath is an issue. These heaters can be easily removed for periodic cleaning.

Over-the-side immersion heaters are available in three models:

Over-the-side immersion heaters are for applications where installing a heater through the side wall of a vessel is not convenient. These immersion heaters are easy to install and can be moved from one tank to another without the need to drain the tank.

Over-the-side immersion heaters are ideal for applications where scale or sludge build-up on the heater sheath is an issue. These heaters can be easily removed for periodic cleaning.

Over-the-side immersion heaters are available in three models:

- straight "L" shaped for heating the bottom of rectangular tanks

- circular “O” shaped for heating the bottom of round tanks

- Rectangular shaped that are hung on the side lip of the tank to provide side wall heating.

Industrial Applications

- WATER TANKS

- VISCOUS OILS

- SALTS AND SOLVENTS

- FREEZE PROTECTION

- CAUSTIC SOLUTIONS

- PARAFFIN

- DEGREASING TANKS

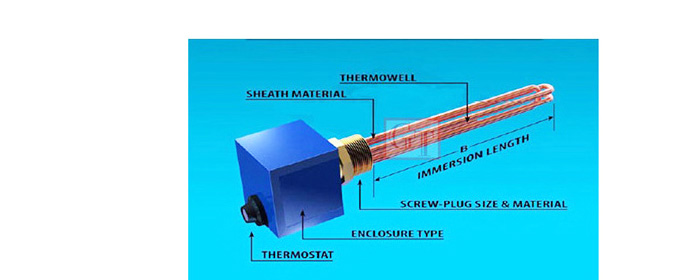

General Features

- Weather/moisture proof terminal box (NEMA 4).

- Single phase or three phase formations

- The possibility of adding heater banks for higher kilowatt output

- Different sheath materials that can meet design parameters and conditions of the liquid being heated.

- Not heated vertical riser pipes for bottom of tank heaters.

- Stand-off legs that support bottom of tank heaters and prevent them from touching the tank floor.

Optional Features

- Vertical riser can be made in any height

- Hazardous Location (NEMA 7) terminal enclosures

- Passivation - when required

- Special fitting for closed top

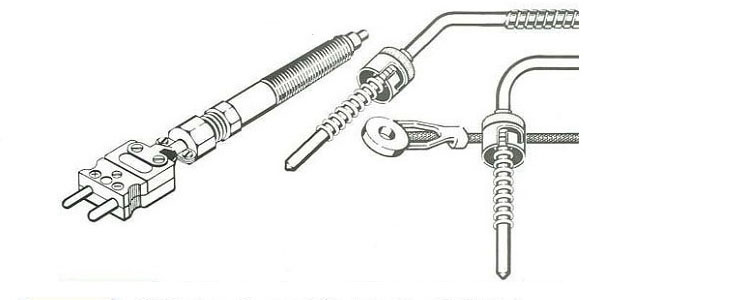

- Built-in thermostats, thermocouples, and high limit thermocouples